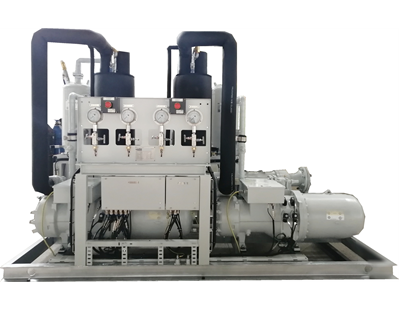

Glory Bright water- cooled deck unit offers a simple system design for marine application, increases system reasonability by providing self-contained package for comfort conditioning, eases operation and maintenance. Cabinet casing: GI or SS 316L. Customized design. Ex-proof type as optional.

· Product Features

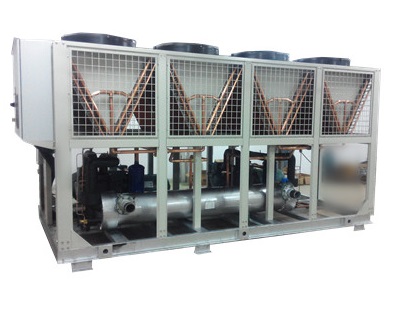

Multiple compressors with independent circuits is more cost saving

Multiple compressors (Scroll, screw or reciprocating type) allow flexible adjustment according to user's load, ensuring higher part-load efficiency. We offer established compressor technology for dependable, efficient, and durable performance. With less moving parts, and continuous refrigerant ?ow,compressors are quiet in operation. Each compressor has independent refrigerant circuit and individual fusing. Each refrigerant circuit is provided with discharge and suction pressure transducers for monitoring and easy diagnostics. Screw type adopt twin-screw compressor achieves high efficiency.

High Reliability

1. Independent refrigerant circuits minimize unit shut down.

2. Multiple compressors provide back up for each other.

3. Complete protection function ensures the unit running smooth.

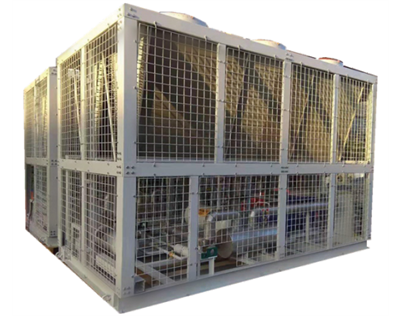

High-efficiency Condenser

Condenser heat exchangers offer the latest technology in heat transfer surface design to give you maximum efficiency and compact design. Water-side and refrigerant-side design enhancements minimize both energy consumption and tube fouling. Corruption resistance copper nickel tube B10 or B30 as optional for sea water cooled deck unit. Sea-water condenser can use SS316L end cover and tube plate to resist the corruption and last long life span.

Refrigerant Circuit

Independent refrigerant circuits will be furnished on each unit. All unit piping will be copper, with brazed joints. The liquid line will include a field connection shutoff valve with charging port located on each condenser circuit. Suction line connections are provided on each refrigeration circuit at the suction valve. Filter drier and sight glass are installed on each refrigerant circuit.

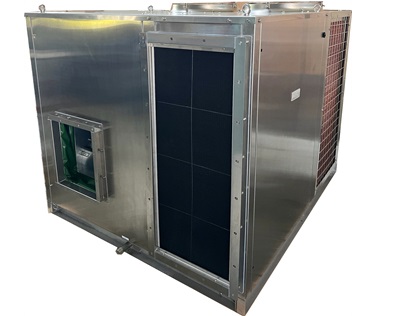

Centrifugal Fan & Motor

Units are supplied with double inlet, backward curved centrifugal fans. All wheels are statically and dynamically balanced to ISO1940 and AMCA 204-G2.5 Standards. All fans after assembly are trim-balanced to ISO1940 and AMCA204-G2.5 Standards. All bearings are either deep groove ball type with an adaptor sleeve or spherical roller bearings type sealed at both sides. Motors are totally enclosed fan cooled type with class F insulation to IP 55 protection. The special design motor and fan base frame provide a very simple and flexible installation and servicing method for fan and motor adjustment. Fan is mounted on vibration isolation springs and connected on the inlet side with a canvas flexible connection, minimizing vibration and noise transmission. Base frames are completely isolated from the unit casing to avoid vibration in cabinet.

Cooling & Heating Coil (Stainless steel electric heater as optional)

Professional software coil design, 4 row or 6 row with row split, each refrigerant circuit covering entire coil face in 2-compressor units. In 4 compressor units, the coil is row split and has intertwined circuiting to activate entire coil face when any compressor is started. DX cooling coils shall be ARI certified and constructed of seamless copper tubing mechanically expanded to the aluminum fins or cooper fins. Blygold coating or E-coating as optional to protect aluminum fin or copper fin during long term exposed in marine environment.

Structure & Paint

The unit structure is heavy-gauge, galvanized steel. This galvanized steel is coated with powder paint. Exterior surfaces are protected with two or three layers coated on steel frame or stainless steel frame. Foundation fabricated with hot dipped galvanized steel with durable machinery paint.

AHU part frame gives high strength and stability, corrosion resistant coated, excellent insulation values. Long life high quality gaskets are also used to ensure perfect sealing. Double skin insulated panels constructed with pre-painted galvanized steel (SS316L as optional). High density rigid CFC (foamed polyurethane)was pressure injected between two sheets to give high strength insulated double skin panels. Panels are simply screwed or spring locked to frame. Standard panel thickness are 25~50 mm with insulation density of 45~50 kg / m3.

Control panel & Safety Protection Function

The DX condensing unit and AHU are controlled by a microprocessor-based or PLC control cabinet. The control panel provides control of system operation and monitoring of system status, sensors, actuators, relays and switches. The screen details all operations and parameters. Protection on low temperature, low oil pressure, high/ low refrigerant pressure, electric leak, and compressor overload, high/low electrical voltage and phase lack, etc.

Factory Test

Each unit shall undergo a rigorous factory-run test prior to shipment and factory test sheets shall be available upon request. The factory test shall include balancing of the completed fan assembly, a compressor run check, a complete run test of all electrical components and safeties (including proper control sequencing ), a leak check of all refrigerant circuits, and a final unit FAT performance inspection.