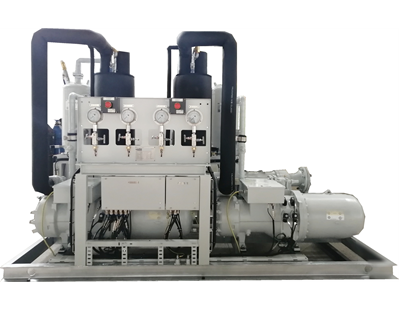

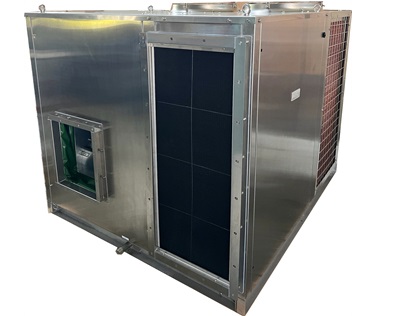

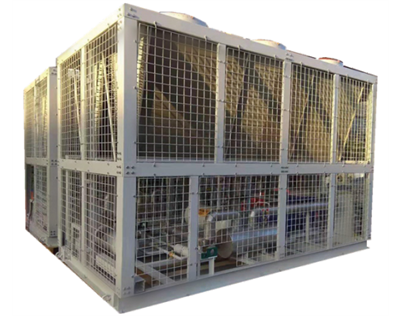

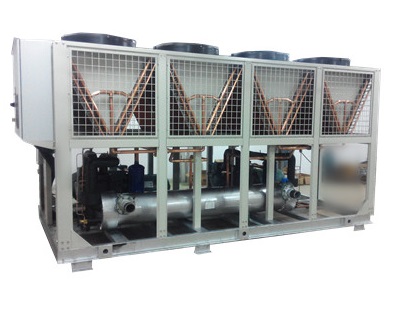

Glory Bright Sea water-cooled (Fresh water-cooled) condensing units, with out-of-date design and One-stop solution for marine application. It is distinguished for its chlorine-free refrigerant, super efficiency & reliability, easy maintenance and low running cost. Condensing Units are the perfect refrigeration components for all air conditioning applications that use DX central station air handling which cooling capacity up to 800kw. They are designed for indoor installation.

Full/part load mode is more cost saving

Screw type adopt twin-screw compressor achieves high efficiency.

Multiple compressors (Scroll, screw or reciprocating type)allow flexible adjustment according to user's load, ensuring higher part-load efficiency.

High reliability

Independent refrigerant circuits minimize unit shut down.

Multiple compressors provide back up for each other.

Complete protection function ensures the unit running smooth.

High-efficiency heat exchangers

Condenser heat exchangers offer the latest technology in heat transfer surface design to give you maximum efficiency and compact design. Water-side and refrigerant-side design enhancements minimize both energy consumption and tube fouling. Corruption resistance copper nickel tube B10 or B30 as optional for sea water cooled chiller unit. Sea-water condenser can use SS316L end cover and tube plate to resist the corruption and last long life span.

Oil Separator

Effective oil separation is achieved by gravity dropout of oil from the refrigerant gas as velocity decreases upon entering the separator, and by mesh pads to provide final gas/oil separation before gas enters the condenser. A large internal volume and oil reservoir means greater liquid tolerance.

Refrigerant circuit

Independent refrigerant circuits will be furnished on each unit. All unit piping will be copper, with brazed joints. The liquid line will include a field connection shutoff valve with charging port located on each condenser circuit. Suction line connections are provided on each refrigeration circuit at the suction valve. Filter drier and sight glass are installed on each refrigerant circuit.

Control panel & Safety Protection Function

The DX condensing unit and AHU are controlled by a microprocessor-based control cabinet. The control panel provides control of system operation and monitoring of system status, sensors, actuators, relays and switches. The screen details all operations and parameters. Protection on low temperature, low oil pressure, high/ low refrigerant pressure, electric leak, and compressor overload, high/low electrical voltage and phase lack, etc.

Paint

The unit structure is heavy-gauge, galvanized steel. This galvanized steel is coated with baked-on powder paint. Exterior surfaces are protected with two or three layers coated on steel frame or stainless steel frame. Foundation fabricated with hot dipped galvanized steel with durable machinery paint.

Shipment

Protective covering is furnished on the motor, Control Center and unit-mounted controls.