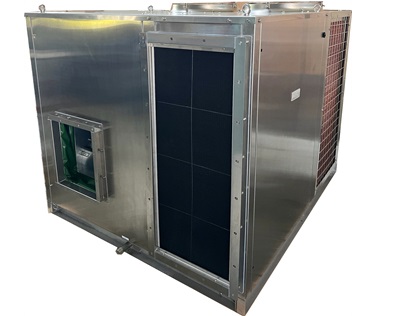

· Product Overview

Glory Bright air handling units design and construction is unequaled in quality and serviceability which used for multi-function air treatment, including cooling, heating, humidifying, dehumidifying, purifying, etc. Its unique design gives the strength and durability for industrial and marine applications Min. air flow unit 2000m3/h and Max. air flow unit 140000m3/h. We can also custom-design according to your special requirements.

· Air flow: 2000~90000m3/h

· Customized design

· Casing: GI / SS316L

· EX-proof type as optional.

· Product Features

· The Frame & Panels

The frame gives high strength and stability, corrosion resistant coated, excellent insulation values. Long life high quality gaskets are also used to ensure perfect sealing. Double skin insulated panels constructed with pre-painted galvanized steel (SS316L as optional). High density rigid CFC (foamed polyurethane)was pressure injected between two sheets to give high strength insulated double skin panels. Panels are simply screwed or spring locked to frame. Standard panel thickness are 25~50 mm with insulation density of 45~50 kg/m3.

· Fan & Motor

Units are supplied with double inlet, backward curved centrifugal fans. All wheels are statically and dynamically balanced to ISO1940 and AMCA 204-G2.5 Standards. All fans after assembly are trim-balanced to ISO1940 and AMCA204-G2.5 Standards. All bearings are either deep groove ball type with an adaptor sleeve or spherical roller bearings type sealed at both sides. Motors are totally enclosed fan cooled type with class F insulation to IP 55 protection. The special design motor and fan base frame provide a very simple and flexible installation and servicing method for fan and motor adjustment. Base frames are completely isolated from the unit casing to avoid vibration in cabinet.

· Cooling & Heating Coil (Stainless steel electric heater as optional)

Standard coils are constructed from copper tubes mechanically bonded to aluminum or copper fins, with threaded copper headers, all contained in a galvanized steel frame.

Coil options are:

--Anti-corrosion coated coil or E-coating.

--Steam distributor heating coils.

--Evaporator coils.

--Copper fins.

–Stainless steel frame

All coils are computer selected to achieve the optimum psychometric efficiency with low air and water pressure drops. All coils are leak tested at 28bar with a maximum design pressure of 25bar. Condensate pans are a "dry pan" design, manufactured from stainless steel. Aluminum or SS304/ SS316 droplet eliminators are fitted after cooling coils when the air velocity exceeds 2.5m/s.

· Excellent quality for other components:

--Humidifiers: Steam Humidifier/ Electrode Humidifier/ Evaporative Humidifier/ High-pressure atomizing humidifier, etc

--Heat recovery: Plate Heat Exchanger/ Thermal Wheel Recovery/ Heat Pipe Recovery/ Coil Heat Recovery.

--Filter: Synthetic or glass-fiber media panel filters, class G2 to G4 arranged in galvanized steel frames or sliding rails. Synthetic or glass-fiber media bag filters, class F5 to F9 arranged in galvanized steel and aluminum alloy frames with gaskets to avoid air bypass. High efficiency compact cell filters, class H10 to H13, fixed with brackets, nuts and bolts or clamps to a heavy galvanized steel gasket structure. Stainless steel frame adopted for marine application.

--Damper (SS316L as optional): Damper shall have high strength extruded aluminum blade, ABS drive-gear, and shall be mounted internally / externally. The blades shall be fitted with "O"-type sealing gasket. Shafts and control rods shall be of steel or copper and shall be purpose designed to suit the actuators. The damper shall be controlled by means of manual or motorized. Final dimension can to be specified by customer.

· Easy maintenance:

All panels can be easily removed on site by unscrewing or unlocking outside of the unit. Access door shall be provided, where necessary to allow inspection and service. Inspection window and water proof lamp are recommended for fan section and any other sections as required.