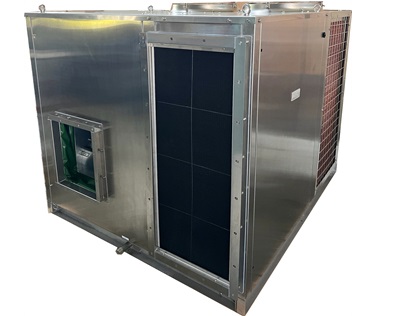

Glory Bright air-cooled scroll chillers are an effective all-in-one package that is easy to install and easy to maintenance. They cost less to purchase and operate quietly and efficiently. Chillers utilize top-quality components to ensure years of reliable operation. Chiller shall include, but is not limited to: A complete system with not less than two independent refrigerant circuits, hermetic scroll compressors, direct expansion type evaporator, air-cooled condenser, refrigerant, lubrication system, interconnecting wiring, safety and operating controls including capacity controller, control center, motor starting components, and special features as specified herein or required for safe, automatic operation.

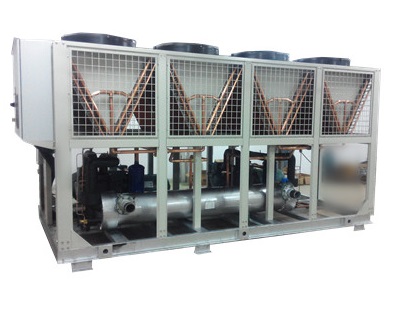

Compressor

Air-cooled scroll chillers use ultra quiet, high-efficiency rotary scroll compressors (COPELAND or DANFOSS brand), operated in independent circuit for greater efficiency at partial loads.

Structure

We adopt cold-rolled steel for maximum structural integrity. The zinc-dipped and powder painted galvanized frame provides the best protection on the market for corrosion resistance. SS316L material is optional.

Condenser coil

Several options are available to match coil construction to the site conditions for the best durability. Refer to the Environmental Corrosion situation. Internally enhanced, seamless copper tubes mechanically expanded into aluminum alloy fins or copper fins with full height collars. Blygold coating or E-coating as optional to protect aluminum fin or copper fin during long term exposed in marine environment.

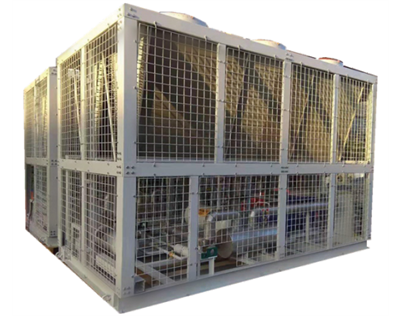

Condensing Fans (Axial type)

Shall be dynamically and statically balanced, direct drive, corrosion resistant glass fiber reinforced composite blades molded into low noise, full airfoil cross section, providing vertical air discharge from extended orifices for efficiency and low sound. Each fan is in its own compartment to prevent cross flow during fan cycling. Guards made of coated galvanized steel. SS316L material fan as optional based on project request. Anti-sparkling design applied for ex-proof usage.

Fan Motors: High efficiency, direct drive, 3-phase, insulation class “F”, current protected, Totally Enclosed Air-Over (TEAO), rigid mounted, with double sealed, permanently lubricated, ball bearings.

Refrigeration circuit

Refrigerant circuit components shall include replaceable-core filter drier, moisture indicating sight glass, thermal expansion valve, discharge service valve and liquid line service valves, and complete operating charge of both refrigerant and compressor oil.

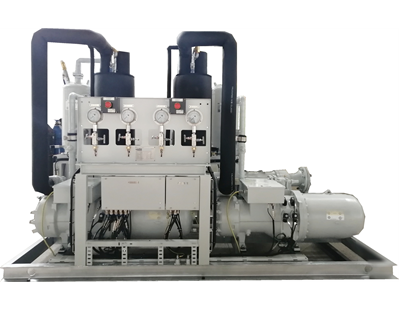

Cooler (Evaporator)

Shell-and-tube type as standard type (plate type as optional), direct expansion. Tubes shall be internally enhanced seamless copper type rolled into tube sheets.. Shell shall be insulated with foam (closed-cell) with a maximum K factor of 0.28. 5. Design shall incorporate a minimum of 2 independent direct-expansion refrigerant circuits. Cooler shall be tested and stamped in accordance with ASME standard.

Microprocessor controller

Microprocessor controls overall unit operation. Its central executive routine controls a number of processes simultaneously. These include internal timers, reading inputs, analog to digital conversions, fan control, display control, diagnostic control, pump control, output relay control, demand limit, capacity control, head pressure control, and temperature reset, etc.

Customized design.

EX-proof type as optional.